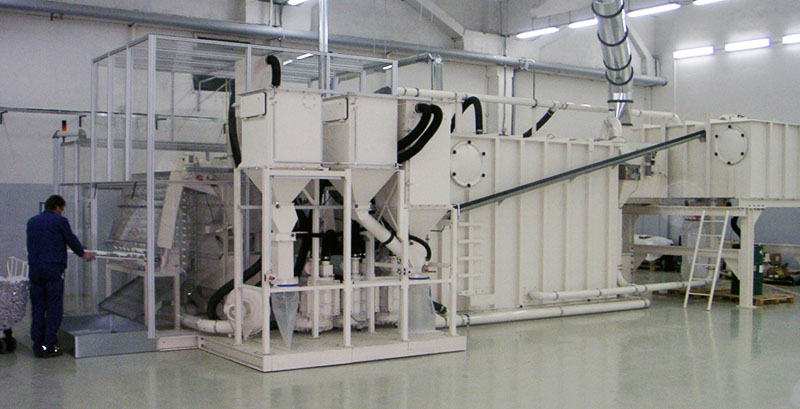

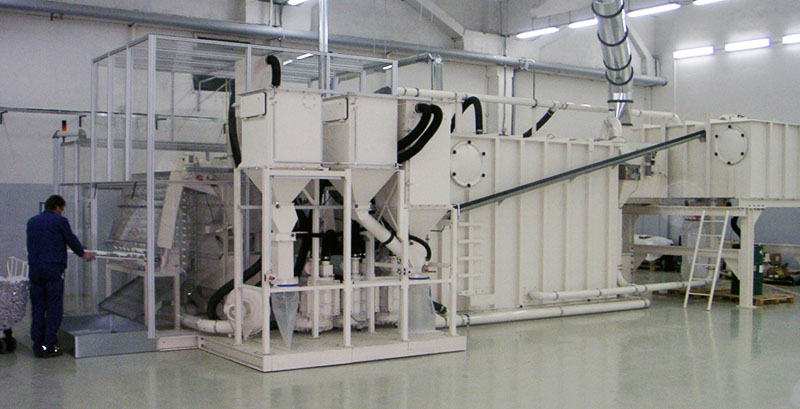

Lamp recycling “system herborn“

The patented mobile and stationary lamp recycling method “system herborn” ensures a professional, environmentally friendly and economical recycling of discharge lamps containing harmful substances, outmatching by far the regulations imposed by law.

The patented mobile and stationary lamp recycling method “system herborn” ensures a professional, environmentally friendly and economical recycling of discharge lamps containing harmful substances, outmatching by far the regulations imposed by law.

“system herborn” use air for the transport of all material inside the equipment. This guarantees an absolutely closed system in all its components. The rate of wear is therefore minimized.

The lamps are loaded onto the loading system. From there, the fluorescent lamps are fed onto an automatic conveyor system into an enclosed receiving facility, where the end caps of the lamps are separated from the glass and the glass is crushed.

The pieces of glass and metal are fed into the combustion chamber of an indirectly fired oven in order to vaporise the remaining mercury.

The end caps are supplied into an end cap cleaning system. The rest-materials attaching the caps are removed largely mechanically in this system. The cap-outbreak (broken glass) is secreted over a filter-system.

The end caps are supplied into an end cap cleaning system. The rest-materials attaching the caps are removed largely mechanically in this system. The cap-outbreak (broken glass) is secreted over a filter-system.

The air stream for the conveying circuit is produced by side canal compressors. The design of the system is such that the processing areas of the unit are kept in a relative vacuum. This means that no hazardous materials are allowed to escape into the environment.

The material is then conveyed into a pressure-tight container. At this stage the secondary material undergoes a subsequent time controlled heat treatment to minimize the residual mercury contamination.

The air stream containing the hazardous material passes through a heat exchanger before entering the active carbon filter. The relatively high temperature (generated through compression) is cooled down to the optimal temperature for the removal of mercury by binding it to the active carbon.

The entire process air is fed to the working and lamp feeding section, so that the harmful substances generated there are sucked off by the working section and fed into the system. The intoxicated air is led through filter systems and, after undergoing a sophisticated process, cleansed by an activated-carbon filter.

All dust filters used in this unit have been tested by the German "Berufgenossenschaftlichen Institut für Arbeitssicherheit (BIA)" - an industry run institute for safe working practices - for their efficiency.

All dust filters used in this unit have been tested by the German "Berufgenossenschaftlichen Institut für Arbeitssicherheit (BIA)" - an industry run institute for safe working practices - for their efficiency.

This technological principle is groundbreaking for the recycling of lamps and is used successfully in several countries.

Herborn provides an overall concept for the disposal of discharge lamps, designed to meet the individual demands of the customer and the respective country.

Mobile lamp recycling unit “system herborn” / Recycling on site

With our recycling concept of “mobile on-site recycling” the logistic effort can be significantly reduced because: With our mobile recycling systems we ensure a quick and straightforward recycling of the lamps right where the waste (lamps) was collected. The ecologic complex and costly transport becomes unnecessary.

With our recycling concept of “mobile on-site recycling” the logistic effort can be significantly reduced because: With our mobile recycling systems we ensure a quick and straightforward recycling of the lamps right where the waste (lamps) was collected. The ecologic complex and costly transport becomes unnecessary.

From the economic point of view, it is not necessary to use the full working capacity of a system on a certain location, and investment costs are reduced in the start-up phase. When necessary or in case of an increase in lamp quantities, it is easily possible to request a stationary system instead of a mobile one at short notice.

The otherwise necessary exchange of the container systems can be omitted which means that the number of circulating containers as well as the respective investment costs are minimized.

The otherwise necessary exchange of the container systems can be omitted which means that the number of circulating containers as well as the respective investment costs are minimized.

This method is used in different countries and is especially suitable for recycling large quantities of linear fluorescent lamps on different locations.

Recyclingtechnology „system herborn“ for CFL, HID, LED-lamps

For the processing (recycling) of discharge lamps from lamp programs of the respective manufacturers, which can be used in most different operating areas and are just as different concerning the form, the technology “system herborn” was expanded through special admission systems which make possible mechanical decomposition, substance separation and final treatment of the non-straight lamps (Ring-Form, U-Form, CFL, LED, …).

For the processing (recycling) of discharge lamps from lamp programs of the respective manufacturers, which can be used in most different operating areas and are just as different concerning the form, the technology “system herborn” was expanded through special admission systems which make possible mechanical decomposition, substance separation and final treatment of the non-straight lamps (Ring-Form, U-Form, CFL, LED, …).

The processing systems of the plant technology guarantee a separation of the lamps construction parts through substance criteria so that a further utilization of the secondary substances is possible.

The technical conception of the special form recycling plant “system herborn” guarantees also that there cannot be released any pollutants to the environment during the processing. The whole area of the plant, in which pollutants can be released, is subject to under inflation during the processing. Therefore the polluted exhausted air from all areas of the plant is sucked off and inevitably led through an activated carbon filter. A microprocessor controlled control and monitoring system guarantees the precise functioning according to the given physical and mechanical-technical data. When deviating from the given desired values the entire plant stops automatically. The fault point is shown on the display so that the occurred fault points can be easily located and cleared.

The CFL lamps are emptied onto the feeding band of the recycling system. The enclosed sucking system makes sure that all emissions are sucked into the recycling unit. The lamps are feed by the conveyor belt into the centrifuge-sieve crusher for CFL lamps. The complete feeding system is housed; no pollutants can reach during the process into the environment out of the processing unit for CFL lamps.

The compact fluorescent lamps and the odd-shaped lamps are fed onto a band conveying system and from there into an inlet port of a speed-controlled centrifuge and sieve separation drum. On the basis of the exactly fixed speed, the glass bulbs are separated from the base parts with the inbuilt electronic without most of the bases and electronics parts being destroyed.

The broken bulb glass is transported by a sucking hose into the basic stationary fluorescent lamp recycling unit “system herborn” for tube lamps. There the glass will undergo the complete cleaning and processing procedure (thermal (if ordered), magnetic, etc.) of the glass from the tube lamps. The lamp bases remaining in the centrifuge (plastic and electronics-parts) can be transferred directly into a container where they undergo a thermal treatment by an electrical heating device. After this thermal treatment the plastic and metal parts can be channeled out. Like the basic unit the installation stands under constantly under-pressure. Consequently no pollutants can reach during the process into the environment out of the processing unit for CFL lamps.

Mercury Distilling plant for fluorescent powder and mercury containing material

The recycling material (stored in metal barrels) is manually connected with a special docking system to the evaporator. After feeding of the evaporator the heating process starts. The principle is a vacuum evaporation with product temperatures of appr. 350°C.

The recycling material (stored in metal barrels) is manually connected with a special docking system to the evaporator. After feeding of the evaporator the heating process starts. The principle is a vacuum evaporation with product temperatures of appr. 350°C.

The evaporated mercury is condensed in a heat exchanger. After the glass is cleaned, the product is discharged into a 200 liter barrel again.

The vacuum, condensation and exhaust cleaning system is installed in the downstream of the evaporator. It is used for forming the vacuum inside the evaporator. Inside the condensator the evaporated mercury is condensed and collected. The installed safety filter units behind the vacuum pump guarantee a save operation.

The vacuum, condensation and exhaust cleaning system is installed in the downstream of the evaporator. It is used for forming the vacuum inside the evaporator. Inside the condensator the evaporated mercury is condensed and collected. The installed safety filter units behind the vacuum pump guarantee a save operation.

Complete control system installed in control cabinet. Suitable for manual and automatic operation. Inclusive PLC and Touchpanel.

Options and Technical Features:

Pallet/box turning/unloading system for TFL lamps

The pallets or the boxes are put into the automatic turning and unloading system of the feeding system. The pallets and boxes are turned and emptied onto the feeding band of the recycling unit. The feeding of the system is covered by a special housing and the enclosed sucking system makes sure that the emissions on the workplace are sucked into the system. No preselection of the lamps to length and diameter.

Feeding system for CFL lamps.

The lamps are feed by the conveyor belt into the centrifuge-sieve crusher for CFL lamps.

Thermal processing CFL lamps

The additional thermal processing station (container) of the CFL plastic parts and metal parts guarantees a reduction of contamination at these parts.

Crusher-installation

The lamps were crushed under under-pressure and the end-caps were separated from the glass parts. The crusher-installation for the glass-tubes consists of a main-crusher and a second crusher.

Glass-separators

The material-stream promoted through under pressure into a separator is cleaned of carried along dust-particles once again. A security-step possibly still severs carried along metal-components in the glass-cycle and supplies these metal-cycle.

End cap-cleaning

The end caps are supplied into an end cap cleaning system. The rest-materials attaching the caps are removed largely mechanically in this system. The cap-outbreak (broken glass) is secreted over a filter-system.

Thermal processing of the cap-outbreak

After the end cap cleaning the separated cap outbreak can be additionally processed by a heating screw and is channeled out.

Filterunit (Sinter plate filter) for fluorescent powder

The filters (built-in) are specifically tailor-made sinter plate filters with self cleaning function controlled over a program and with a long lifetime (Maintenance free).

Thermal treatment (Special furnace with gas burner) incl. industrial gas burner and gas installation

The sorted material-streams (glass/metal) are separately fed to the inbuilt gas fired furnace. The glass is indirectly heated in special chambers which are separated from the gas fired furnace chamber to approximately 500°C. The end-caps are channeled by a screw through the furnace (the screw is separated from the gas fired furnace chamber too) and are heated to approximately 200°C. For both material-streams a heating cycle is predetermined and continuously. From there the material is transported by a conveyor screw into the glass container and into the end-cap container for the further heating procedure. All emissions from this treatment are sucked through powder filter into the activated carbon filter.

Container for glass (TFL) and Container for metal-caps (TFL) with integrated thermal treatment and electric heating device.

Here the glass and the metal caps undergoes a subsequent time controlled heating treatment to minimize the residual mercury contamination.

Active carbon filters

The active carbon filter has capacity of approximately 1 to of special impregnated filter carbon. Reduced current-speed of the process air secures an optimal bond of the mercury.

Cooling-systems for process air

Before admission of the warmed up process air into the active carbon filter, the air is cooled down by a cooling-system. An optimal bond of the mercury to the active carbon is reached by this temperature.

Outlet-air safety filter for toxic powder

Before admission of the process air into the active carbon filter, a Goretex-filter is connected in series to clean around the exhaust air-stream of measurable dust-particles.

Material-sorting takes place on basis of:

- Magnetically separation by magnetic separation cylinder (NdFeB)

- Pneumatically separation

- Mechanically separation

Automatic self-unloading device of glass

The glass removal is carried out during the processing. So a continuous drainage is possible without great losses of time. The internal self-unloading system is part of the integrated suction system of the unit. The unloading was processed under under-pressure and all dust is separate and transport over the dust-filter system. The result is an automatic and dust free unloading of the glass.

Weighing unit for glass (big-bag)

The glass is conveyed to a filling station, where two big bags are available for the glass filling. Both big bags are weighed with a pallet weighting system and after the first big-bag is filled up to a predetermined weight the drainage is automatically switched to the second big bag.

Automatic self unloading device of end-caps

The caps are removed at the bottom of the storage tank with a screw conveyor and fed into a big bag. The result is an automatic and dust free unloading of the caps.

Housing

The feeding-area of the system (feeding conveyor) of the lamps is equipped with a housing that is sucked permanently. All emissions from the workplace and the feeding area are sucked into the unit and through the inbuilt powder filter into the activated carbon filter.

We will be pleased to help you enhance your "system herborn" recycling plant with any number of additional customized features.

The requests we get from our customers include automatic weighing and filling of secondary raw materials, specialized treatment systems for extra waste, noise barriers, an automatic cleanout system for lamp containers, screening units for sorting the dust, monitoring of emissions. Whatever your request, it will be a pleasure to fulfil it.

Suction mechanism for glass, with automatic weighing and dust-free cleanout system Suction mechanism for glass, with automatic weighing and dust-free cleanout system |

|

Filterplants for dusts, with screening and dust-free bagging Filterplants for dusts, with screening and dust-free bagging |

|

Thermal reheating container for waste (alternating system) Thermal reheating container for waste (alternating system) |

|

Temperature monitoring and extinguishing system for active-charcoal containers Temperature monitoring and extinguishing system for active-charcoal containers |

The patented mobile and stationary lamp recycling method “system herborn” ensures a professional, environmentally friendly and economical recycling of discharge lamps containing harmful substances, outmatching by far the regulations imposed by law.

The patented mobile and stationary lamp recycling method “system herborn” ensures a professional, environmentally friendly and economical recycling of discharge lamps containing harmful substances, outmatching by far the regulations imposed by law. The end caps are supplied into an end cap cleaning system. The rest-materials attaching the caps are removed largely mechanically in this system. The cap-outbreak (broken glass) is secreted over a filter-system.

The end caps are supplied into an end cap cleaning system. The rest-materials attaching the caps are removed largely mechanically in this system. The cap-outbreak (broken glass) is secreted over a filter-system. All dust filters used in this unit have been tested by the German "Berufgenossenschaftlichen Institut für Arbeitssicherheit (BIA)" - an industry run institute for safe working practices - for their efficiency.

All dust filters used in this unit have been tested by the German "Berufgenossenschaftlichen Institut für Arbeitssicherheit (BIA)" - an industry run institute for safe working practices - for their efficiency.

With our recycling concept of “mobile on-site recycling” the logistic effort can be significantly reduced because: With our mobile recycling systems we ensure a quick and straightforward recycling of the lamps right where the waste (lamps) was collected. The ecologic complex and costly transport becomes unnecessary.

With our recycling concept of “mobile on-site recycling” the logistic effort can be significantly reduced because: With our mobile recycling systems we ensure a quick and straightforward recycling of the lamps right where the waste (lamps) was collected. The ecologic complex and costly transport becomes unnecessary. The otherwise necessary exchange of the container systems can be omitted which means that the number of circulating containers as well as the respective investment costs are minimized.

The otherwise necessary exchange of the container systems can be omitted which means that the number of circulating containers as well as the respective investment costs are minimized. For the processing (recycling) of discharge lamps from lamp programs of the respective manufacturers, which can be used in most different operating areas and are just as different concerning the form, the technology “system herborn” was expanded through special admission systems which make possible mechanical decomposition, substance separation and final treatment of the non-straight lamps (Ring-Form, U-Form, CFL, LED, …).

For the processing (recycling) of discharge lamps from lamp programs of the respective manufacturers, which can be used in most different operating areas and are just as different concerning the form, the technology “system herborn” was expanded through special admission systems which make possible mechanical decomposition, substance separation and final treatment of the non-straight lamps (Ring-Form, U-Form, CFL, LED, …). The recycling material (stored in metal barrels) is manually connected with a special docking system to the evaporator. After feeding of the evaporator the heating process starts. The principle is a vacuum evaporation with product temperatures of appr. 350°C.

The recycling material (stored in metal barrels) is manually connected with a special docking system to the evaporator. After feeding of the evaporator the heating process starts. The principle is a vacuum evaporation with product temperatures of appr. 350°C. The vacuum, condensation and exhaust cleaning system is installed in the downstream of the evaporator. It is used for forming the vacuum inside the evaporator. Inside the condensator the evaporated mercury is condensed and collected. The installed safety filter units behind the vacuum pump guarantee a save operation.

The vacuum, condensation and exhaust cleaning system is installed in the downstream of the evaporator. It is used for forming the vacuum inside the evaporator. Inside the condensator the evaporated mercury is condensed and collected. The installed safety filter units behind the vacuum pump guarantee a save operation.